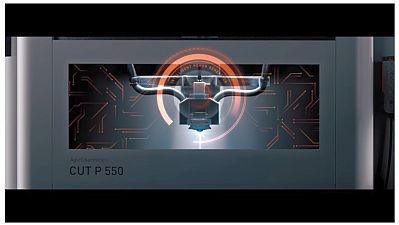

Highly Intuitive HMI Highlights New, Advance-Designed EDM

GF Machining Solutions' new CUT P 550 Pro EDM features the new highly intuitive Uniqua human/machine interface (HMI), Intelligent Power Generator (IPG) technology and advanced QUADREX® machine design. All CUT P Pro machines are also well suited for every application, provide increased productivity and offer several automation options for lights-out production.

The new Uniqua HMI delivers optimal functionality and ergonomics in a 19" vertical touchscreen, full keyboard and mouse. For the utmost compatibility, Uniqua supports legacy file types from various EDM manufacturers and can create, import, modify and execute sequential (ISO-based) and object-oriented (dynamic) programs from previous versions of VISION and AC CUT HMI 2. With such capabilities, Uniqua works integrally with major CAD/CAM programs.

With IPG technology, the CUT P 550 Pro generates surface finishes as smooth as Ra 0.08 µm and heightens accuracy using integrated thermal regulation that allows the machine to achieve positioning precision of ±2 µm.

To protect the machine's X, Y, Z, U and V axes, its linear scales and rotary encoders form a double measuring system. In the event of a collision, the system differentiates between the linear and the rotary encoder, and an energy absorber system automatically stops the axes without damage to machine or workpiece. This full protection applies at machine speeds of up to 3m/min.

The QUADRAX® mechanical system enables the CUT P 550 Pro's table, work tank and dielectric liquid to remain stationary, as well as the workpiece, which allows the machine to accommodate heavier parts. Independent U/V and X/Y axes with equal length (X = U travel; Y = V travel), constant, lower mass and completely independent movement produce large, precise tapered cuts. Additionally, a Rhenocast machine base offers lower thermal conductivity and vibration damping.

Automation solutions for the CUT P 550 Pro include Automatic Slug Management (ASM), Automatic Slug Welding (ASW) and the option of a retractable Renishaw mechanical touch probe to measure workpiece planarity and position on the machine's worktable. Scalable automation options from System 3R include a WorkPartner 1+ compact robot that can feed up to two wire-cutting EDM machines for more than two days to maintain unattended production.

All CUT P Pro Series machines optimize production for electronics, automotive, medical and mold and die manufacturers with more than 600 pre-programmed cutting processes. On the CUT P 550 Pro, these cover a wide range of parts from less than 0.04" to 15.75" (less than 1 mm to 400 mm) in height and weights up to 3,307 lb (1,500 kg), in materials such as steel, carbide, copper, aluminum, titanium, polycrystalline diamond (PCD) and graphite.

Wires are available from 0.003" to 0.013" (0.07 mm to 0.33 mm) diameters. Based on the Spark Track technology from GF Machining Solutions, the ISPS (Intelligent Spark Protection System) on each machine prevents wire breakage. The company's intelligent iWire process detects variations in the workpiece profile and adapts wire spool unwinding speed accordingly to reduce wire consumption.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::